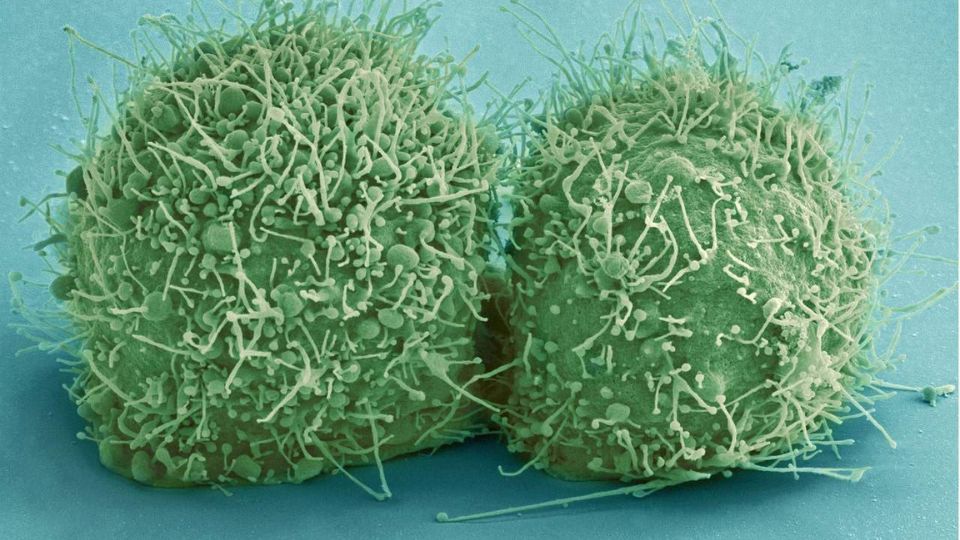

Many biopharmaceutical and biological products are based on (different) cell-type fermentation.

Biopharmaceutical products can be either intracellular or extracellular metabolites that have a pharmacological effect.

Fermentation, as a whole, includes upstream and downstream good manufacturing practice (GMP) multi-stage processes whose purpose is to yield the required biopharmaceutical therapeutic material that is pure and active, and which is released according to relevant quality standards and specifications.

Fermentation can begin using either genetically modified or unmodified cells such as bacteria, fungi, plant, and mammalian material. Usually, large-scale fermentation processes will be performed in stainless steel or single-use bioreactors (for more information about single-use reactors, refer to single-use equipment in the biopharmaceutical industry).

At the cell inoculation and fermentation stages, biological mass (products or metabolites) will be accumulated in the bioreactor as a result of the cell growth and proliferation processes.

Inoculums Preservation and Storage

Cell culture preservation and storage can be performed using the following preservation and storage techniques:

Agar slant/dish

Usually being used in microbiology laboratories and not for animal cell culture.

Storage conditions: 2-8°C.

Maximal storage period: 12 months.

Ultra freezing

Fits all cell cultures and is being used for industrial usage.

Storage conditions: (-70)°C for bacteria and fungi (freezer) and (-196)°C for plant and mammalian cell culture (liquid Nitrogen cryostat).

Maximal storage time: 5 years.

Lyophilization

Liquid drying technique based on gas sublimation principles under controlled (low) temperatures and pressure conditions. Lyophilization is suitable for bacteria and fungi cell storage and is used for industrial usage. Lyophilization is relatively costly but is considered a high-quality, yield, and validated preservation technique.

Storage conditions: Room temperature.

Maximal storage period: 10 years

Air drying

Low humidity air and “dry conditions” will cause “spore former” bacteria and fungi cells to create spores and as a result, enable cell storage.

Storage conditions: Room temperature.

Maximal storage period: Years (depends on cell type)

Cell Banks

Cell storage for industrial usage (immediate and long term) purposes should minimize potential risks such as cell stress, impurities, and mix-ups in order to assure preserved cells’ vitality, condition, purity and identification are being kept during short and prolonged storage periods.

Cell storage in cell banks is being performed in controlled conditions, using validated and calibrated main storage equipment (usually freezers) in addition to backup equipment, both usually will include redundancy between cooling systems, monitored storage conditions, and other GMP (Good Manufacturing Practice) standards should be kept in order to avoid temperature fluctuations, damage, and cell stress during the storage period.

Cell banks storage system should be stable, backed up (connected to backup generators), and validated prior to usage.

Cell bank content should be managed according to all GMP (Good Manufacturing Practice) and GSP (Good Storage Practice) standards. Moreover, the cell banks storage system should be connected to the monitoring and alarm system that were validated successfully as part of a computerized system/software validation program.

There are two levels of cell banks that are used for clinical trials and industrial usage:

Master cell bank- Used for working cell bank creation and long-term storage. Usually, stored cell culture will be diluted after thawing.

Master cell bank should be continuously monitored and tested periodically for cell identification, viability, purity, phenotype, genotype, stability, and storage tube identity and labeling.

Working cell bank- Used for short and medium-term cell storage for cell culture trials/research and fermentation purposes on a day-to-day basis. Working cell bank should be periodically tested for cell viability and identification and should be maintained in a validated state.

Using a biological laminar air flow hood, the frozen cell tube (after graduate thawing), colony, or lyophilisate are transferred into Erlenmeyer containing the appropriate sterile medium in the required volume.

The Erlenmeyer is being incubated overnight in a shaker incubator at the required incubation temperature (and shaking speed) defined in Table No.1, till the required turbidity level is achieved. Using aseptic techniques in a biological laminar air flow hood, the required inoculum volume will be transferred into the sterile bio-reactor for the upstream fermentation stage.

Cells Growth Substances

Water

Water purity grade for media preparation can begin as Purified Water (PW) for bacteria and yeast, PW and HPW (Highly Purified Water) for plant cells, and Highly Purified Water (HPW) and Water For Injection (WFI) for mammalian cells fermentation. The water system should be of sanitary design, and pharmaceutical grade and should be validated before usage and continuously monitored.

Air

Air is an Oxygen source for cell growth as it contains ~21% O2 and therefore should be supplied and dissolved in the media during fermentation. Moreover, instrument air is supplied for fermentation process equipment components pressurization and pneumatic operation purposes.

Process air that is in contact with the vessel/equipment’s inner surface, media, or product should be dry, particle, microorganisms, and oil-free air. Oil Free Compressed Air system should be pharmaceutical grade and should be validated before usage and continuously monitored.

Carbon

Carbohydrates, Glucose, Glycerol, Lactose, etc. are essential basic substances for cell growth and proliferation. Carbohydrates cannot be used for animal cell media.

Nitrogen

Amino acids, Ammonia, yeast extract, etc. are essential basic substances for cell growth and proliferation.

Macro elements

Salts that contain elements such as Na, Cl, Mg, S, K

Micro elements

Salts that are required in low quantities for fermentation

Serum

Serum usage as a growth media is usually forbidden for usage in large quantities. Serum-free media can be purchased or developed for specific fermentation process needs and is used as a substitute serum.

The serum is very rich in essential substances and is suitable for most mammalian cell lines’ growth. Fetal calf/calf serums are usually characterized in ‘lot to lot’ variation and may contain Endotoxins, viruses, hormones etc.

Before usage, the serum will be analyzed at least for sterility (including mycoplasma detection), growth curves, cloning efficiency, and visually (microscope).

Osmotic pressure-maintaining agents

Vitamins

Buffers

Buffers are added to media, in order to avoid pH fluctuations during fermentation.

Anti-foam agents

Usually, for large-scale fermentation processes and as a result of high sheer mixing forces, the foam may be created. Silicone/vegetable oils and other anti-foam agents should be added in addition to anti-foam mechanical components that can be installed in the bio-reactor.

Inoculum Growth

There are many challenges in inoculum growth, such as keeping cells viable after recovery, genotypic identity after storage, high levels of biological mass, etc.

Table 1. Cell Growth Conditions

| Fermentation parameter | Bacterial cells | Yeast

cells |

Mold

cells |

Plant

cells |

Mammalian cells |

| pH | 6.0-7.5 | 4.5-6.0 | 4.5-7.0 | 6.8-7.6 | 6.9-7.6 |

| Temperature [°C] | 30-37 | 30-37 | 30-37 | 24-28 | 36-38 |

| Aeration | Aerobic & Anaerobic | Aerobic & Anaerobic | Aerobic | Aerobic | Aerobic |

| Inoculum volume/total | 1-5% | 1-10% | 1-10% | 10-20% | 105/ml |

Fermentation

Generally, there are two different cell fermentation techniques:

State Solid fermentation

Cell growth on a solid substrate.

Submerged fermentation

Cells are submerged in the media and separated into batch, fed-batch, continuous and perfusion fermentation.

Batch fermentation

Non-continuous process. No substrate and/or cells are being added into the bio-reactor during the entire fermentation process (except for air, anti-foam, and pH adjustment solutions).

Fed-batch fermentation

Non-continuous process. Part of the media substrates is being fed into the bio-reactor during the fermentation process (Carbon, Nitrogen sources etc.) in addition to air, anti-foam, and pH adjustment solutions addition.

Figure No. 1- Batch Vs. fed batch fermentation

Continuous fermentation

Fresh media is added into the bio-reactor at the same rate spent media is being taken out of the bio-reactor. Cells are kept in the logarithmic phase longer in comparison to other fermentation techniques (ideal for biological materials/products that are being produced by the cells in the logarithmic phase of the cells).

Perfusion fermentation

Cells are immobilized on beads/discs or filtered and retained in the bio-reactor through the fermentation process and are not taken out of the bio-reactor during spent media takeout as in continuous fermentation (higher biological mass yield).

In-Process Controls

Critical parameters through the fermentation process should be controlled, monitored, and tested as part of the validation stage (OQ, PQ, and PPQ). Critical parameters should be kept within defined validated limits during fermentation, separation, and purification, and filling processes.

Biological parameters

Culture purity (in every stage, starting from the inoculums stage) will be verified using a microscope, agar-rich medium, and selective medium (Petri dish incubation) through the entire fermentation process in addition to cells and product concentrations, microbial contamination testing etc.

Physical parameters

Temperature, pressure, flow rates (gases/liquid), agitation speed, foam detection, viscosity, biological mass concentration weight/volume, turbidity etc.

Chemical parameters

pH, dissolved gases concentration (O2, CO2), redox potential, gases concentration in outlet etc.

Sterilization

Most media types will be sterilized using heat, except for animal cell media which is usually sensitive to high temperatures, therefore will be sterilized usually by filtration.

All equipment components that are in direct or indirect contact with substances or products should be constructed of stainless steel 316 with a low roughness level.

Instrumentation elements that are in direct or indirect contact with substances or products should be constructed of stainless steel 316 with a low roughness level and sterile.

Sterilization and sterile storage hold times parameters and procedures should be validated in addition to Cleaning Validation and clean hold time validations.

Sterilization is more critical at downstream stages than upstream stages due to the risk-based approach.

Qualification and Validation

Utilities Validation

Critical utilities will be validated for Installation and Operational Qualification (IQ and OQ). Non-critical utilities (have no impact on product quality and/or GMP) can be qualified by commissioning only.

Fermentation Equipment Validation

Fermentation equipment such as bio-reactors, pumps, fermentors, and vessels should be validated for Installation, Operational and Performance Qualification (IQ, OQ and PQ)

Fermentation, separation and purification system Validation

Equipment should be validated for Cleaning Validation and clean hold time.

Analytical Equipment and system Validation

Should be validated for Installation and Operational Qualification (IQ, OQ) as well as for Computerized System Validation (CSV) in case the system includes software according to Annex 11, 21CFR part 11, and GAMP 5 requirements.

(For more information about computerized system validation refer to CE/FDA-compliant Computerized System and Software Validation).

Analytical methods Validation

Analytical methods in usage for product detection, impurities, cleaning agents, and microbial detection should be validated.

CIP (Clean In Place) Skids Validation

Should be validated for Installation, Operational, and Performance Qualification including spray device qualification (spray devices installed on equipment).

Control panel and HMI Validation

Equipment and skids control panels and HMIs will be validated for Computerized System Validation (CSV) according to Annex 11, 21CFR part 11, and GAMP 5 requirements.

(For more information about software and Computerized System Validation refer to CE/FDA-compliant Computerized System and Software Validation)

SIP (Steam In Place) Validation

Sterilization and sanitization processes should be validated for Installation, Operational, and Performance Qualification (IQ, OQ and PQ).

Sterile hold time Validation

The sterile state of equipment during storage should be validated in case the equipment is not being sterilized prior to batch production.

Cleaning Validation

Equipment cleaning processes such as bio-reactors, vessels, chromatography columns, ultrafiltration, small equipment, and others should be validated (For more information refer to the Cleaning Validation article).

Clean hold time Validation

Cleaned equipment storage period and conditions after cleaning should be validated.

(For more information refer to the Cleaning Validation article).

Growth promotion Validation

Growth promotion factors in media should be validated using cell vitality and growth rate calculations.

Media shelf life storage Validation

Media shelf life growth material concentration and sterilization state should be validated for defined storage conditions and duration.

Product storage Validation

Batch storage conditions, duration, microbial contamination, and shelf life should be validated.

Cell bank storage systems

Cryostates, freezers, refrigerators, and freezing rooms should be validated for Installation, Operational, and Performance Qualification (IQ, OQ and PQ).

(For more information about computerized system validation refer to CE/FDA-compliant Computerized System and Software Validation).

Cell bank alarm and monitoring computerized system should be validated for Computerized System Validation (CSV) according to Annex 11, 21CFR part 11 and GAMP 5.

Product manufacturing procedure Validation

The entire manufacturing process should be validated for Process Performance Qualification (PPQ) for the required number of batches.

Shipment Validation

Final product shipment and supply chain equipment should be validated for Installation, Operational and Performance Qualification (IQ, OQ and PQ) for transportation systems as well as for transportation routes (for more information refer to article Good Storage and Distribution Practice, cold chain safety and validation)

The biological mass in the bioreactor should meet quality and microbial standards during and after the upstream fermentation stages to assure the presence of the “right” microorganisms, cell type populations, and/or metabolites in the bioreactor.

As part of the downstream process stage, the biological therapeutic material will be purified through several extraction, separation and purification processes until the required identity, concentration, purity, and quality of the therapeutic biological material/product is achieved.